The Best Strategy To Use For Outsourced Warehousing And Fulfillment

Wiki Article

Outsourced Warehousing And Fulfillment Things To Know Before You Get This

Table of ContentsOutsourced Warehousing And Fulfillment for BeginnersOutsourced Warehousing And Fulfillment for BeginnersThe Facts About Outsourced Warehousing And Fulfillment UncoveredOutsourced Warehousing And Fulfillment for DummiesSome Known Facts About Outsourced Warehousing And Fulfillment.Outsourced Warehousing And Fulfillment for Beginners

As even more firms outsource their warehousing, they'll need to make certain they're picking the best partner to ensure the greatest level of solution. It's easier to take the following step in your endeavor currently that you have a company understanding of warehousing. Having the ability to determine the right stockroom solutions as well as relevant partnerships can spend some time; don't rush yourself.Warehousing is the procedure of keeping as well as shipping physical items in a warehouse. Storehouses can be used in different business setups for keeping goods prior to shipping them to a specific place or various customers. A business like Walmart may use a storehouse to keep its products in mass and ship them to its shops when stock drops short, and things are required to be placed on shelves.

You may have noticed terms stockroom and also circulation center are used reciprocally. Well, practically they are different. A storehouse is just a structure that is utilized to keep supply. Whereas a warehouse not just shops the supply, yet likewise gives an order satisfaction facility through the processes of picking, packaging, and delivery.

Not known Incorrect Statements About Outsourced Warehousing And Fulfillment

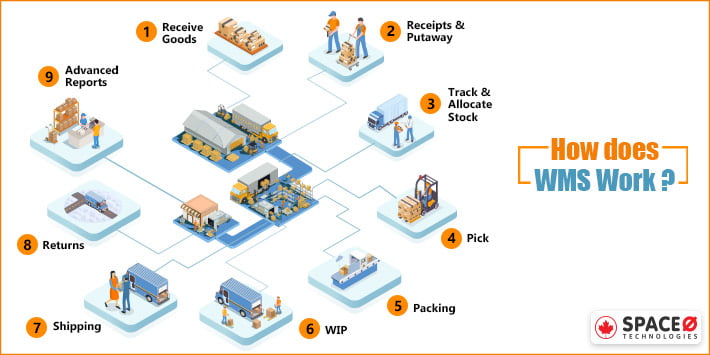

An item that reoccurs in and also out of a stockroom goes through a number of processes. Typically, 2 primary processes take care of an item from entering into the stockroom to being shipped out as well as everything in between. These are Inbound as well as Outgoing procedures. The inbound procedure is obtaining and saving items from a supplier to a storehouse or a gratification center.

These are as follows: After the trailer is docked at the storehouse, workers examine the stock to make sure that all things that were anticipated are present and also are not harmed. Then the supply is assigned License Plate Figures (LPNs) and considered putaway. After the stock is evaluated in the receiving process, it is taken to storage where it is stored.

Some stockrooms keep items together based on the product kind or called for storage space temperature etc. to optimize storage places to maximize area use. The outbound Process is the picking, packing, as well as delivery of products from the warehouse to a customer or end individual. The outgoing process is further split into the following processes - outsourced warehousing and fulfillment.

What Does Outsourced Warehousing And Fulfillment Do?

Selecting is the process of gathering all the items in order from their particular storage space areas as well as moving them to a hosting location. When all products in an order are selected and also given a staging location, the following action is to get them all set to be shipped to the customer or end user.

The last action in finishing an order after it has actually been chosen and packed is to select an ideal provider, lots the order on the provider and also ship it to continue reading this the consumer's delivery address. All the above steps as well as procedures involved with warehousing can conveniently be managed and monitored using a Stockroom Administration check out here System.

A warehouse monitoring system (WMS) contains software program and also procedures that enable companies to regulate and carry out stockroom procedures from the time goods or products enter a storehouse up until they vacate. Warehouses rest at the center of production and supply chain operations since they hold all of the material made use of or produced in those processes, from raw products to finished goods. outsourced warehousing and fulfillment.

Indicators on Outsourced Warehousing And Fulfillment You Should Know

For example, if basic materials are not received correctly or components are misplaced in a storehouse, the supply chain may be slowed or interrupted. WMSes are crucial in making certain that these processes work smoothly by tracking inventory and ensuring that goods are kept and arranged correctly, in addition to shipped and tracked precisely.Number 1. Each of the 3 primary SCM systems has a specific role in managing orders and sharing data with the various other two. The WMS manages the information as well as procedures associating with the motion of items through a stockroom. Figure 1 shows each system's duty in processing orders and also the types of information they need to show to each various other to ensure that the right product obtains to the consumer on time.

Its function in stock is to track the inventory data that is available in from barcode readers as well as radio regularity identification (RFID) tags and also upgrade the supply monitoring module navigate to this site in the ERP system to ensure it has the current details. A combination web link synchronizes the supply data that is stored in the ERP system and the WMS.

Getting My Outsourced Warehousing And Fulfillment To Work

The TMS is where the delivery process is managed. It is essentially a database of thorough info regarding shipping providers however is likewise a transactional and communication system for preparation, implementing and also tracking the deliveries. Sometimes a TMS will certainly be incorporated with the WMS to make it possible for better control of the incoming and also outbound logistics jobs that happen at the user interface of stockrooms as well as products carriers, such as palletization of goods, labor organizing, lawn monitoring, lots structure as well as cross-docking., including zone selecting, wave picking and batch selecting. Storage facility employees can also utilize whole lot zoning and also task interleaving features to direct the pick-and-pack jobs in the most reliable way., which makes it possible for the WMS to send out expenses of lading (B/L) ahead of the delivery, create packaging checklists and billings for the delivery and also send out advancement delivery alerts to receivers.

The main attribute of a cloud-based WMS versus the standard on-premises system is that the software is held and also managed by the WMS vendor or a cloud provider. This takes the burden of mounting, handling and updating the system off the company's IT department. Since they are simpler to install as well as less costly to handle, cloud-based WMSes often tend to be preferred by SMBs.

9 Easy Facts About Outsourced Warehousing And Fulfillment Shown

Pros of cloud-based WMS consist of the following: Faster implementation. Traditional on-premises WMSes can typically take months to apply, whereas cloud-based WMS deployments can be completed in weeks, depending on the intricacy. This indicates that organizations have a much faster path to a positive ROI and also can benefit from the cloud WMS capabilities earlier, which is a massive advantage in the fast-paced modern economic situation.Report this wiki page